Lexus RX (RX 350L, RX450h) 2016-2025 Repair Manual: Daytime Running Light Relay Circuit

DESCRIPTION

The main body ECU (multiplex network body ECU) controls the daytime running lights.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- Inspect the fuses for circuits related to this system before performing the following procedure.

-

Before replacing the main body ECU (multiplex network body ECU), refer to Registration.

Click here

.gif)

.gif)

PROCEDURE

| 1. | PERFORM ACTIVE TEST USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Main Body / Active Test.

(e) Perform the Active Test according to the display on the Techstream.

Body Electrical > Main Body > Active Test| Tester Display | Measurement Item | Control Range | Diagnostic Note |

|---|---|---|---|

| Daytime Running Light | Daytime running lights | OFF/ON | This Active Test can only be performed when the customization item DRL function is set to "ON" using the Techstream. |

| Tester Display |

|---|

| Daytime Running Light |

OK:

Daytime running lights illuminate.

| OK | .gif) | PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

|

| 2. | CHECK SEMICONDUCTOR POWER INTEGRATION ECU |

(a) Using a voltmeter, check the signal reading of the semiconductor power integration ECU.

Click here .gif)

OK:

Output signal reading is normal.

| NG | .gif) | INSPECT SEMICONDUCTOR POWER INTEGRATION ECU (RESULTS OF SIGNAL READING CHECK) |

|

| 3. | CHECK HARNESS AND CONNECTOR (SEMICONDUCTOR POWER INTEGRATION ECU POWER SOURCE AND BODY GROUND) |

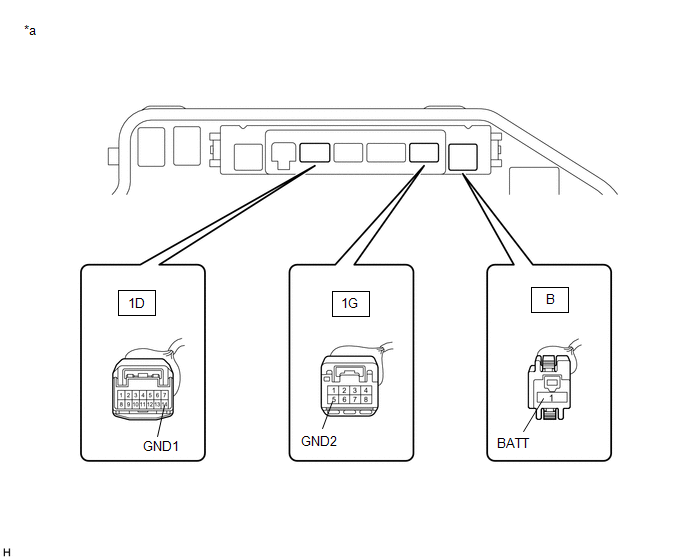

| *a | Component without semiconductor power integration ECU connected (Engine Room Relay Block and Junction Block Assembly) | - | - |

(a) Remove the semiconductor power integration ECU from the engine room relay block and junction block assembly.

Click here .gif)

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| B-1 (BATT) - Body ground | Always | 11 to 14 V |

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| 1D-14 (GND1) - Body ground | Always | Below 1 Ω |

| 1G-5 (GND2) - Body ground | Always | Below 1 Ω |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 4. | CHECK HARNESS AND CONNECTOR (SEMICONDUCTOR POWER INTEGRATION ECU - INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY) |

(a) Disconnect the 2C instrument panel junction block assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| 1D-9 (-S) - 2C-28 | Always | Below 1 Ω |

| 1D-9 (-S) or 2C-28 - Body ground | Always | 10 kΩ or higher |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 5. | INSPECT INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY |

| *a | Component without harness connected (Instrument Panel Junction Block Assembly) | - | - |

(a) Remove the main body ECU (multiplex network body ECU) from the instrument panel junction block assembly.

Click here .gif)

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| 2C-28 - MB-25 (DRLE) | Always | Below 1 Ω |

| NG | .gif) | REPLACE INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY |

|

| 6. | REPLACE SEMICONDUCTOR POWER INTEGRATION ECU |

(a) Replace the semiconductor power integration ECU with a new one.

Click here .gif)

|

| 7. | CHECK OPERATION (DAYTIME RUNNING LIGHTS) |

(a) Check the operation of the daytime running lights.

OK:

Daytime running lights operate normally.

| OK | .gif) | END (SEMICONDUCTOR POWER INTEGRATION ECU WAS DEFECTIVE) |

| NG | .gif) | REPLACE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

Headlight Dimmer Switch Circuit

Headlight Dimmer Switch Circuit

DESCRIPTION The main body ECU (multiplex network body ECU) receives the following switch information:

Light control switch in DRL OFF*, tail, head, AUTO position

Dimmer switch in high, low or hig ...

Turn Signal Light Circuit

Turn Signal Light Circuit

DESCRIPTION The combination meter assembly controls the illumination and turning off of the rear turn signal lights. WIRING DIAGRAM PROCEDURE 1. CHECK OPERATION (REAR TURN SIGNAL LIGHTS) (a) ...

Other materials:

Lexus RX (RX 350L, RX450h) 2016-2025 Repair Manual > Lighting (ext): Front Turn Signal Light Bulb

ReplacementREPLACEMENT CAUTION / NOTICE / HINT HINT:

Use the same procedure for the RH side and LH side.

The following procedure is for the LH side.

PROCEDURE 1. REMOVE COOL AIR INTAKE DUCT SEAL Click here 2. REMOVE FRONT TURN SIGNAL LIGHT BULB (a) for RH Side: (1) Remove the bolt. (2) Dis ...

Lexus RX (RX 350L, RX450h) 2016-2025 Repair Manual > Seat Variable Cushion Switch: Installation

INSTALLATION CAUTION / NOTICE / HINT CAUTION: Wear protective gloves. Sharp areas on the parts may injure your hands. HINT:

Use the same procedure for the RH side and LH side.

The following procedure is for the LH side.

PROCEDURE 1. INSTALL SEAT VARIABLE CUSHION SWITCH (a) Install the sea ...

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Owners Manual

- For your information

- Pictorial index

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Lexus Display Audio system

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Repair Manual

0.0149

.gif)