Lexus RX (RX 350L, RX450h) 2016-2025 Repair Manual: Installation

INSTALLATION

PROCEDURE

1. INSTALL TORQUE CONVERTER ASSEMBLY

| (a) Turn the front oil pump drive gear so that either key is at the top and place a matchmark on the transaxle housing to indicate the position of the key. |

|

| (b) Place a matchmark on the torque converter assembly so that the position of its groove is clearly indicated. |

|

| (c) Align the matchmark on the torque converter assembly with the one on the transaxle housing and engage the splines of the input shaft with the turbine runner splines. NOTICE:

|

|

| (d) Rotate the torque converter assembly approximately 180° and engage the splines of the stator shaft with the stator assembly. NOTICE:

|

|

| (e) Rotate the torque converter assembly approximately 180° again, align the matchmark on the torque converter assembly with the one on the transaxle housing and insert the keys of the front oil pump drive gear into the grooves of the torque converter assembly. NOTICE:

|

|

(f) Clean the drive plate and torque converter assembly setting bolt holes.

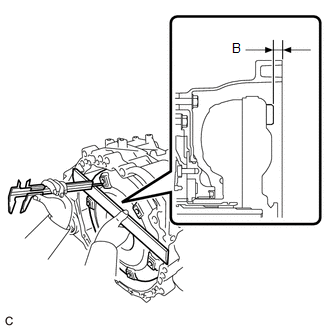

| (g) Using a vernier caliper and straightedge, measure the dimension (A) between the automatic transaxle assembly contact surface of the engine assembly*a and the torque converter assembly contact surface of the drive plate and ring gear sub-assembly*b. NOTICE: Make sure to deduct the thickness of the straightedge. |

|

| (h) Using a vernier caliper and straightedge, measure the dimension (B) shown in the illustration and check that the dimension (B) is more than the dimension (A), which was measured in the previous step. Standard: Dimension (A) + 1 mm (0.0394 in.) or more NOTICE:

|

|

2. INSTALL TRANSMISSION BREATHER SKIRT

(a) Install the transmission breather skirt to the automatic transaxle case sub-assembly with the bolt.

Torque:

12 N·m {122 kgf·cm, 9 ft·lbf}

(b) Engage the 3 clamps to install the transmission breather plug.

3. INSTALL NO. 2 TRANSMISSION CONTROL CABLE BRACKET

(a) Install the No. 2 transmission control cable bracket to the automatic transaxle case sub-assembly with the bolt.

Torque:

12 N·m {122 kgf·cm, 9 ft·lbf}

4. INSTALL REAR ENGINE MOUNTING BRACKET

(a) Install the rear engine mounting bracket to the transaxle housing with the 3 bolts.

Torque:

40 N·m {408 kgf·cm, 30 ft·lbf}

5. INSTALL REAR ENGINE MOUNTING INSULATOR

| (a) Install the rear engine mounting insulator to the rear engine mounting bracket with the through bolt. Torque: 71 N·m {724 kgf·cm, 52 ft·lbf} NOTICE: If tightening the bolt before installation of the front frame assembly, ensure that the edge of the protrusion of the bracket is within the width of the rib. |

|

6. INSTALL ENGINE MOUNTING BRACKET LH

(a) Install the engine mounting bracket LH to the automatic transaxle case sub-assembly with the 4 bolts.

Torque:

40 N·m {408 kgf·cm, 30 ft·lbf}

(b) Engage the transmission breather clamp to the engine mounting bracket LH.

7. INSTALL AUTOMATIC TRANSAXLE ASSEMBLY

(a) Apply clutch spline grease to the surface of the crankshaft that contacts the torque converter assembly centerpiece.

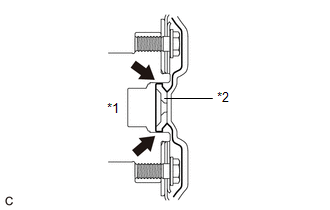

| *1 | Crankshaft |

| *2 | Torque Converter Assembly Centerpiece |

.png) | Clutch Spline Grease |

Clutch Spline Grease:

Toyota Genuine Clutch Spline Grease or equivalent

Maximum Grease Amount:

Approximately 1 g (0.0353 oz)

| (b) Confirm that the knock pins are installed to the engine assembly and are not damaged. |

|

(c) While keeping the engine assembly and automatic transaxle assembly horizontal, align the knock pins with the holes in the automatic transaxle assembly and install the automatic transaxle assembly with the 11 bolts shown in the illustration.

Torque:

Bolt (A) :

64 N·m {653 kgf·cm, 47 ft·lbf}

Bolt (B) :

64 N·m {653 kgf·cm, 47 ft·lbf}

Bolt (C) :

46 N·m {469 kgf·cm, 34 ft·lbf}

Bolt (D) :

43 N·m {438 kgf·cm, 32 ft·lbf}

NOTICE:

- Confirm that the knock pins are installed to the automatic transaxle assembly contact surface of the cylinder block sub-assembly before installing the automatic transaxle assembly.

- Do not forcibly pry on the automatic transaxle assembly.

- Check that the torque converter assembly rotates.

- Bolt (A): 55 mm (2.17 in.)

- Bolt (B): 50 mm (1.97 in.)

- Bolt (C): 41 mm (1.61 in.)

- Bolt (D): 33 mm (1.30 in.)

8. INSTALL ENGINE MOUNTING INSULATOR LH

| (a) Install the engine mounting insulator LH to the vehicle body with the 5 bolts. Torque: 71 N·m {724 kgf·cm, 52 ft·lbf} NOTICE: Tightening order: Temporarily tighten bolt (A) → Fully tighten bolt (B) → Fully tighten bolt (A), (C), (D) and (E) |

|

(b) Install the through bolt and nut.

Torque:

40 N·m {408 kgf·cm, 30 ft·lbf}

HINT:

When tightening the through bolt, keep the nut from rotating.

(c) Install the engine wire to the engine mounting insulator LH with the nut.

Torque:

8.4 N·m {86 kgf·cm, 74 in·lbf}

(d) Engage the clamp.

9. INSTALL FRONT ENGINE MOUNTING BRACKET

(a) Install the front engine mounting bracket to the transaxle housing with the 3 bolts.

Torque:

64 N·m {653 kgf·cm, 47 ft·lbf}

10. INSTALL FRONT ENGINE MOUNTING INSULATOR

Click here .gif)

11. CONNECT NO. 1 TRANSMISSION OIL COOLER HOSE

Click here .gif)

12. INSTALL FRONT FRAME ASSEMBLY

Click here .gif)

13. CONNECT FRONT ENGINE MOUNTING INSULATOR

Click here .gif)

14. CONNECT REAR ENGINE MOUNTING INSULATOR

Click here .gif)

15. INSTALL DRIVE PLATE AND TORQUE CONVERTER ASSEMBLY SETTING BOLT

(a) Remove any adhesive remaining the 6 drive plate and torque converter assembly setting bolts.

| (b) Apply a few drops of adhesive to 2 or 3 threads at the tip of each of the 6 drive plate and torque converter assembly setting bolts. Adhesive: Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent NOTICE: Make sure to install the 6 drive plate and torque converter assembly setting bolts immediately after applying adhesive to prevent foreign matter from attaching to them. |

|

(c) Turn the crankshaft to gain access to the installation locations of the 6 drive plate and torque converter assembly setting bolts and install each drive plate and torque converter assembly setting bolt while holding the crankshaft pulley bolt with a wrench.

Torque:

41 N·m {418 kgf·cm, 30 ft·lbf}

NOTICE:

First install the black colored drive plate and torque converter assembly setting bolt, and then the remaining 5 silver colored drive plate and torque converter assembly setting bolts.

16. INSTALL FLYWHEEL HOUSING UNDER COVER

(a) Install the flywheel housing under cover to the automatic transaxle case sub-assembly with the 2 bolts.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

17. REMOVE ENGINE SUPPORT BRIDGE

(a) Remove SST from the vehicle body.

NOTICE:

Prevent SST from contacting the vehicle body or windshield glass.

18. REMOVE ENGINE HANGER

(a) Remove the 2 bolts and No. 2 engine hanger from the cylinder head LH.

(b) Remove the bolt and No. 1 engine hanger from the cylinder head RH.

19. INSTALL FUEL PUMP PROTECTOR

Click here .gif)

20. INSTALL WIRE HARNESS CLAMP BRACKET

(a) Install the wire harness clamp bracket to the cylinder head RH with the bolt.

Torque:

13 N·m {133 kgf·cm, 10 ft·lbf}

(b) Engage the hose clamp and 3 wire harness clamps.

(c) Connect the air fuel ratio sensor (for Bank 1) connector.

21. INSTALL AIR SURGE TANK TO INTAKE MANIFOLD GASKET

Click here .gif)

22. INSTALL INTAKE AIR SURGE TANK ASSEMBLY

Click here .gif)

23. CONNECT PURGE VALVE (PURGE VSV)

Click here .gif)

24. CONNECT VENTILATION HOSE

Click here .gif)

25. CONNECT NO. 1 RADIATOR HOSE

Click here .gif)

26. INSTALL NO. 1 EXHAUST PIPE SUPPORT BRACKET

Click here .gif)

27. INSTALL FRONT EXHAUST PIPE ASSEMBLY

Click here .gif)

28. INSTALL NO. 1 EXHAUST PIPE SUPPORT BRACKET (for Lower Side)

Click here .gif)

29. INSTALL FRONT DRIVE SHAFT ASSEMBLY

Click here .gif)

30. INSTALL FRONT FENDER APRON SEAL LH

Click here .gif)

31. INSTALL SUSPENSION TOWER DAMPER (w/ Suspension Tower Damper)

Click here .gif)

32. INSTALL FRONT LOWER BUMPER ABSORBER

Click here .gif)

33. INSTALL NO. 3 ENGINE UNDER COVER

Click here .gif)

34. INSTALL FRONT WHEEL OPENING EXTENSION PAD LH

Click here .gif)

35. INSTALL FRONT STABILIZER BAR

Click here .gif)

36. CONNECT WIRE HARNESS

(a) Connect the wire harness to the automatic transaxle case sub-assembly with the bolt.

Torque:

19.1 N·m {195 kgf·cm, 14 ft·lbf}

(b) Connect the transmission wire connector and park/neutral position switch assembly connector.

37. INSTALL NO. 2 VACUUM SWITCHING VALVE ASSEMBLY

Click here .gif)

38. CONNECT TRANSMISSION CONTROL CABLE ASSEMBLY

Click here .gif)

39. INSTALL BATTERY BRACKET REINFORCEMENT

(a) Install the battery bracket reinforcement to the vehicle body with the 2 bolts.

Torque:

20 N·m {204 kgf·cm, 15 ft·lbf}

40. INSTALL BATTERY CARRIER SUB-ASSEMBLY

(a) Install the battery carrier sub-assembly to the vehicle body with the 6 bolts.

Torque:

20 N·m {204 kgf·cm, 15 ft·lbf}

(b) Engage the 2 clamps.

41. INSTALL BATTERY

Click here .gif)

42. INSTALL ECM

Click here .gif)

43. INSTALL STARTER ASSEMBLY

Click here .gif)

44. INSTALL OUTER COWL TOP PANEL SUB-ASSEMBLY

Click here .gif)

45. INSTALL FRONT WIPER MOTOR AND LINK ASSEMBLY

Click here .gif)

46. INSTALL V-BANK COVER SUB-ASSEMBLY

Click here .gif)

47. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable is reconnected.

Click here .gif)

48. ADD ENGINE COOLANT

Click here .gif)

49. INSPECT FOR COOLANT LEAK

Click here .gif)

50. CHECK AUTOMATIC TRANSAXLE SYSTEM

NOTICE:

If automatic transaxle parts have been replaced, refer to Parts Replacement Compensation Table to determine if any additional operations are necessary.

Click here .gif)

Components

Components

COMPONENTS ILLUSTRATION *1 OUTER COWL TOP PANEL SUB-ASSEMBLY - - N*m (kgf*cm, ft.*lbf): Specified torque - - ILLUSTRATION *1 FRONT WHEEL OPENING EXTENSION PAD LH *2 N ...

Removal

Removal

REMOVAL CAUTION / NOTICE / HINT The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during auto ...

Other materials:

Lexus RX (RX 350L, RX450h) 2016-2025 Repair Manual > Quarter Window Glass (w/ Rear No. 2 Seat): Components

COMPONENTS ILLUSTRATION *A for RH Side *B for LH Side *1 FRONT DECK SIDE TRIM COVER *2 REAR DOOR INSIDE SCUFF PLATE *3 REAR DOOR SCUFF PLATE *4 REAR SEAT OUTER TRACK BRACKET COVER LH *5 REAR SEAT OUTER TRACK BRACKET COVER RH *6 REAR SEAT SIDE GARNISH ILLUST ...

Lexus RX (RX 350L, RX450h) 2016-2025 Repair Manual > 4wd Control Switch: Inspection

INSPECTION PROCEDURE 1. INSPECT AWD LOCK SWITCH (COMBINATION SWITCH ASSEMBLY) (a) Inspect the AWD lock switch: (1) Measure the resistance according to the value(s) in the table below. Standard Resistance: Tester Connection Condition Specified Condition 5 (B) - 1 (GND) AWD lock switc ...

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Owners Manual

- For your information

- Pictorial index

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Lexus Display Audio system

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Repair Manual

0.0142