Lexus RX (RX 350L, RX450h) 2016-2025 Repair Manual: Installation

INSTALLATION

PROCEDURE

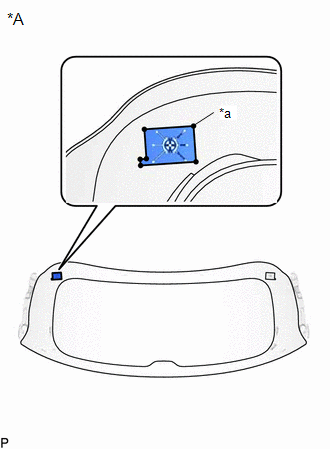

1. INSTALL BACK DOOR GLASS SPACER (w/o Rear No. 2 Seat)

(a) Using a brush or sponge, coat the installation area of 4 new back door glass spacers with primer G.

NOTICE:

- Do not apply too much primer G.

- Allow the primer G to dry for 3 minutes or more.

- Throw away any leftover primer G.

HINT:

If an area other than specified is coated by accident, wipe off the primer G with a clean piece of cloth before it dries.

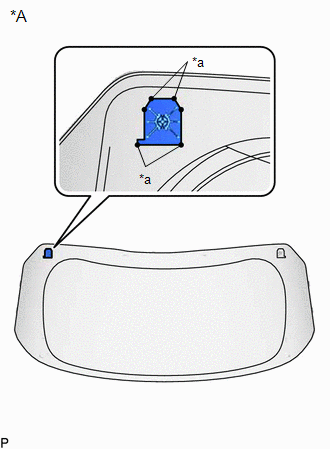

| (b) Install the 4 new back door glass spacers to the back door glass as shown in the illustration. |

|

2. INSTALL BACK DOOR GLASS SPACER (w/ Rear No. 2 Seat)

(a) Using a brush or sponge, coat the installation area of 4 new back door glass spacers with primer G.

NOTICE:

- Do not apply too much primer G.

- Allow the primer G to dry for 3 minutes or more.

- Throw away any leftover primer G.

HINT:

If an area other than specified is coated by accident, wipe off the primer G with a clean piece of cloth before it dries.

| (b) Install the 4 new back door glass spacers to the back door glass as shown in the illustration. |

|

3. INSTALL NO. 1 BACK WINDOW GLASS SPACER (w/o Rear No. 2 Seat)

(a) Using a brush or sponge, coat the installation area of a new No. 1 back window glass spacer with primer G.

NOTICE:

- Do not apply too much primer G.

- Allow the primer G to dry for 3 minutes or more.

- Throw away any leftover primer G.

HINT:

If an area other than specified is coated by accident, wipe off the primer G with a clean piece of cloth before it dries.

| (b) Install the new No. 1 back window glass spacer to the back door glass as shown in the illustration. |

|

4. INSTALL NO. 2 BACK WINDOW GLASS SPACER (w/o Rear No. 2 Seat)

HINT:

Use the same procedure as for the No. 1 back window glass spacer.

5. INSTALL NO. 1 BACK WINDOW GLASS SPACER (w/ Rear No. 2 Seat)

(a) Using a brush or sponge, coat the installation area of a new No. 1 back window glass spacer with primer G.

NOTICE:

- Do not apply too much primer G.

- Allow the primer G to dry for 3 minutes or more.

- Throw away any leftover primer G.

HINT:

If an area other than specified is coated by accident, wipe off the primer G with a clean piece of cloth before it dries.

| (b) Install the new No. 1 back window glass spacer to the back door glass as shown in the illustration. |

|

6. INSTALL NO. 2 BACK WINDOW GLASS SPACER (w/ Rear No. 2 Seat)

HINT:

Use the same procedure as for the No. 1 back window glass spacer.

7. INSTALL LOWER BACK WINDOW MOULDING (w/o Rear No. 2 Seat)

(a) Using a brush or sponge, coat the installation area of a new lower back window moulding with primer G.

NOTICE:

- Do not apply too much primer G.

- Allow the primer G to dry for 3 minutes or more.

- Throw away any leftover primer G.

HINT:

If an area other than specified is coated by accident, wipe off the primer G with a clean piece of cloth before it dries.

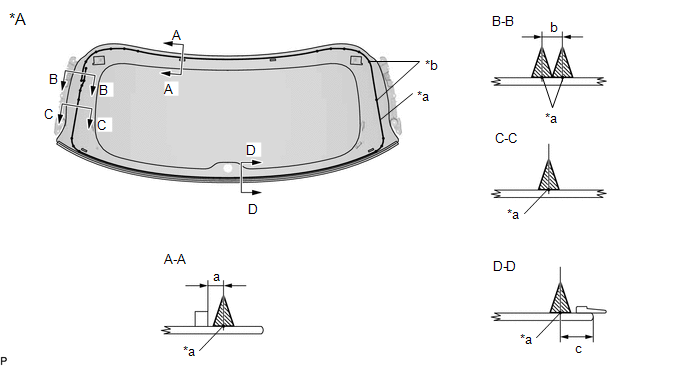

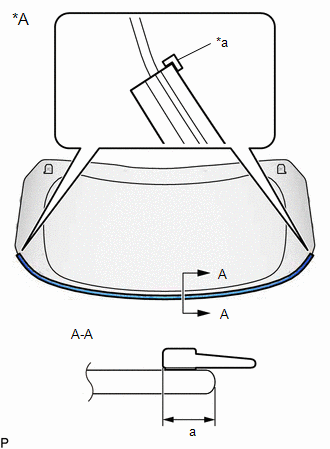

| (b) Install the new lower back window moulding to the back door glass as shown in the illustration. Standard Dimension:

|

|

8. INSTALL LOWER BACK WINDOW MOULDING (w/ Rear No. 2 Seat)

(a) Using a brush or sponge, coat the installation area of a new lower back window moulding with primer G.

NOTICE:

- Do not apply too much primer G.

- Allow the primer G to dry for 3 minutes or more.

- Throw away any leftover primer G.

HINT:

If an area other than specified is coated by accident, wipe off the primer G with a clean piece of cloth before it dries.

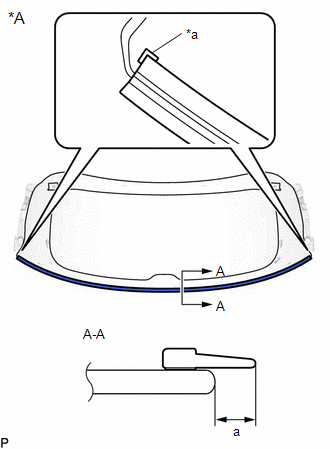

| (b) Install the new lower back window moulding to the back door glass as shown in the illustration. Standard Dimension:

|

|

9. INSTALL BACK DOOR GLASS SUB-ASSEMBLY

| (a) Position the back door glass sub-assembly. (1) Using suction cups, place the back door glass sub-assembly in the correct position. (2) Check that the whole contact surface of the back door glass sub-assembly rim is perfectly even. (3) Align the matchmarks on the back door glass sub-assembly and back door panel. NOTICE: Check that the No. 1 and No. 2 back window glass spacers are engaged to the back door panel correctly. (4) Remove the back door glass sub-assembly. |

|

(b) Using a brush, coat the installation surfaces on the back door panel with primer M.

NOTICE:

- Do not coat the adhesive with primer M.

- Do not apply too much primer M.

- Allow the primer M to dry for 3 minutes or more.

- Throw away any leftover primer M.

HINT:

If an area other than specified is coated by accident, wipe off the primer M with a clean piece of cloth before it dries.

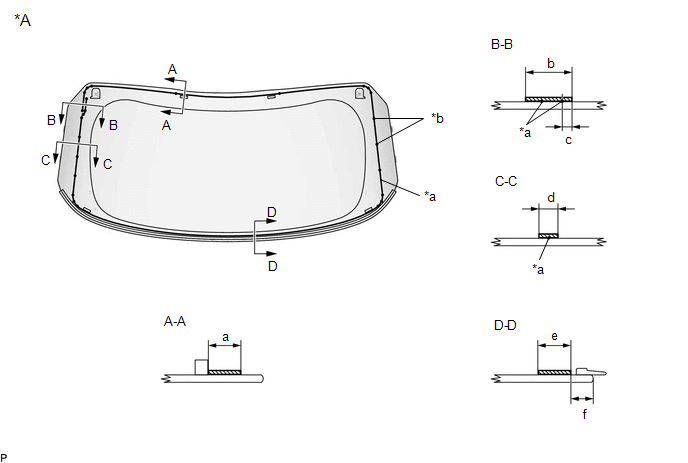

(c) w/o Rear No. 2 Seat:

(1) Using a brush or sponge, coat the adhesive application area with primer G.

| *A | Back Side | - | - |

| *a | Adhesive Positioning Center | *b | Ceramic Notch |

.png) | Primer G | - | - |

Standard Dimension:

| Area | Dimension |

|---|---|

| a | 13.5 mm (0.531 in.) or more |

| b | 19.0 mm (0.748 in.) or more |

| c | 4.0 mm (0.157 in.) |

| d | 11.0 mm (0.433 in.) or more |

| e | 11.0 mm (0.433 in.) or more |

| f | 9.3 mm (0.366 in.) |

NOTICE:

- Do not apply too much primer G.

- Allow the primer G to dry for 3 minutes or more.

- Throw away any leftover primer G.

HINT:

- Apply primer G to the ceramic notches.

- If an area other than specified is coated by accident, wipe off the primer G with a clean piece of cloth before it dries.

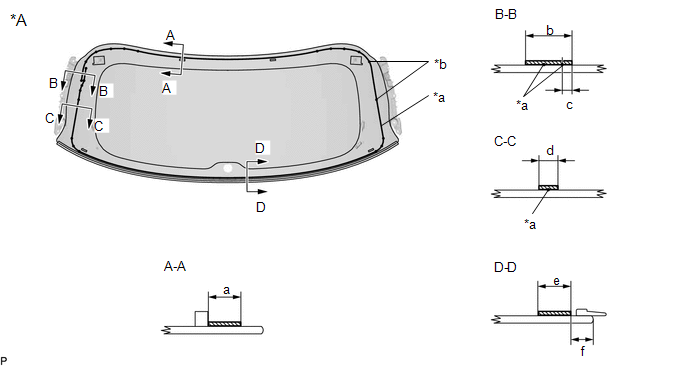

(d) w/ Rear No. 2 Seat:

(1) Using a brush or sponge, coat the adhesive application area with primer G.

| *A | Back Side | - | - |

| *a | Adhesive Positioning Center | *b | Ceramic Notch |

.png) | Primer G | - | - |

Standard Dimension:

| Area | Dimension |

|---|---|

| a | 13.5 mm (0.531 in.) or more |

| b | 19.0 mm (0.748 in.) or more |

| c | 4.0 mm (0.157 in.) |

| d | 11.0 mm (0.433 in.) or more |

| e | 11.0 mm (0.433 in.) or more |

| f | 9.2 mm (0.362 in.) |

NOTICE:

- Do not apply too much primer G.

- Allow the primer G to dry for 3 minutes or more.

- Throw away any leftover primer G.

HINT:

- Apply primer G to the ceramic notches.

- If an area other than specified is coated by accident, wipe off the primer G with a clean piece of cloth before it dries.

(e) Apply adhesive to the back door glass sub-assembly.

Adhesive:

Toyota Genuine Windshield Glass Adhesive (High modulus type) or equivalent

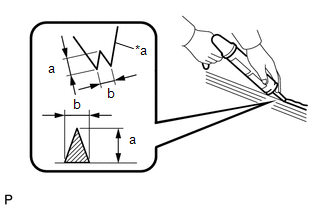

| (1) Cut off the tip of the cartridge nozzle as shown in the illustration. Standard Dimension:

|

|

(2) Load the sealer gun with the cartridge.

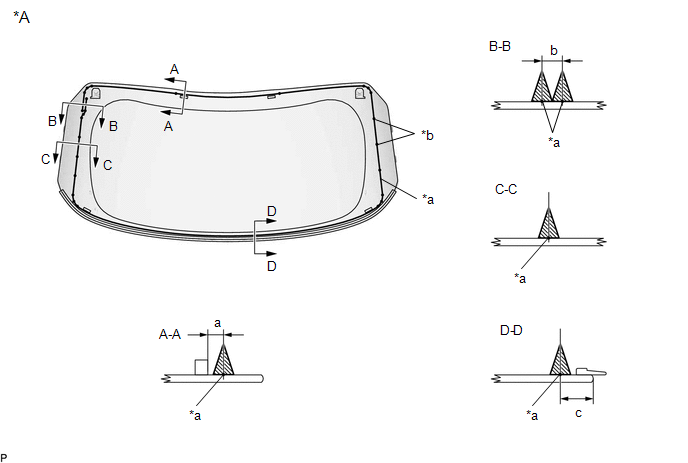

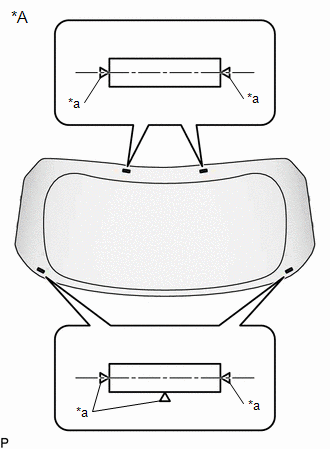

(3) w/o Rear No. 2 Seat:

-

Apply adhesive to the back door glass sub-assembly as shown in the illustration.

*A

Back Side

-

-

*a

Adhesive Positioning Center

*b

Ceramic Notch

.png)

Adhesive

-

-

Standard Dimension:

Area

Dimension

a

6.5 mm (0.256 in.)

b

8.0 mm (0.315 in.)

c

13.3 mm (0.524 in.)

HINT:

Apply adhesive to the ceramic notches.

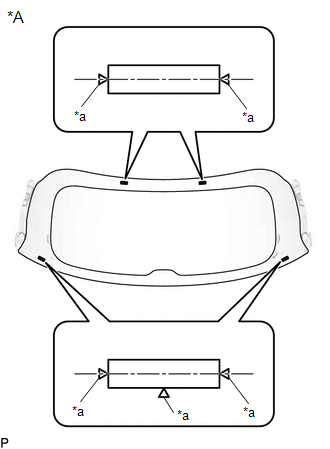

(4) w/ Rear No. 2 Seat:

-

Apply adhesive to the back door glass sub-assembly as shown in the illustration.

*A

Back Side

-

-

*a

Adhesive Positioning Center

*b

Ceramic Notch

.png)

Adhesive

-

-

Standard Dimension:

Area

Dimension

a

6.5 mm (0.256 in.)

b

8.0 mm (0.315 in.)

c

13.2 mm (0.520 in.)

HINT:

Apply adhesive to the ceramic notches.

(f) Install the back door glass sub-assembly.

| (1) Using suction cups, position the back door glass sub-assembly so that the matchmarks are aligned, and press it in gently along the rim. NOTICE:

|

|

(2) Lightly press the front surface of the back door glass sub-assembly to ensure a close fit.

HINT:

Press the glass with force of 98 N (10 kgf, 22.0 lbf) or more.

(3) Using a scraper, remove any excess or protruding adhesive.

(4) Hold the back door glass sub-assembly using protective tape until the applied adhesive becomes hard.

HINT:

Follow the instructions supplied by the adhesive manufacturer or in the corresponding instruction manual for the minimum amount of time necessary to wait before driving the vehicle.

(g) Connect each connector and engage each clamp.

10. INSPECT FOR LEAK

(a) After the adhesive has hardened, apply water from the outside of the vehicle. Check that no water leaks into the cabin.

(b) If water leaks into the cabin, allow the water to dry and add adhesive.

(c) Remove the protective tape.

11. INSTALL REAR WIPER ARM AND BLADE ASSEMBLY (w/o Rear No. 2 Seat)

Click here .gif)

12. INSTALL REAR WIPER MOTOR AND BRACKET ASSEMBLY (w/ Rear No. 2 Seat)

Click here .gif)

13. INSTALL POWER BACK DOOR SENSOR ASSEMBLY LH

Click here .gif)

14. INSTALL POWER BACK DOOR SENSOR ASSEMBLY RH

HINT:

Use the same procedure as for the LH side.

15. INSTALL REAR SPOILER

Click here .gif)

16. INSTALL BACK DOOR OUTSIDE GARNISH SUB-ASSEMBLY

Click here .gif)

.gif)

Removal

Removal

REMOVAL PROCEDURE 1. REMOVE BACK DOOR OUTSIDE GARNISH SUB-ASSEMBLY Click here 2. REMOVE REAR SPOILER Click here 3. REMOVE POWER BACK DOOR SENSOR ASSEMBLY LH Click here 4. REMOVE POWER BACK DOOR ...

Front Passenger Side Power Window Switch

Front Passenger Side Power Window Switch

ComponentsCOMPONENTS ILLUSTRATION *1 POWER WINDOW REGULATOR SWITCH ASSEMBLY *2 POWER WINDOW REGULATOR SWITCH ASSEMBLY WITH FRONT DOOR UPPER ARMREST BASE PANEL RemovalREMOVAL PROCEDURE 1. ...

Other materials:

Lexus RX (RX 350L, RX450h) 2016-2025 Repair Manual > Introduction: Identification Information

Vehicle Identification And Serial NumbersVEHICLE IDENTIFICATION AND SERIAL NUMBERS VEHICLE IDENTIFICATION NUMBER (a) The vehicle identification number is stamped on the vehicle body and on the certification label as shown in the illustration. *1 Vehicle Identification Number *2 Certificati ...

Lexus RX (RX 350L, RX450h) 2016-2025 Repair Manual > Sliding Roof System: How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT HINT:

Use the following procedure to troubleshoot the sliding roof system.

*: Use the Techstream.

PROCEDURE 1. VEHICLE BROUGHT TO WORKSHOP

NEXT 2. CUSTOMER PROBLEM ANALYSIS HINT:

In troubleshooting, confirm that the problem sympto ...

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Owners Manual

- For your information

- Pictorial index

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Lexus Display Audio system

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Repair Manual

0.0137

.png)