Lexus RX (RX 350L, RX450h) 2016-2025 Repair Manual: Right Front Wheel Speed Sensor Circuit Intermittent (C05061F)

DESCRIPTION

The speed sensor detects wheel speed and sends the appropriate signals to the skid control ECU (brake actuator assembly). These signals are used for brake control.

Speed sensor rotors have rows of alternating N and S magnetic poles, and their magnetic fields change when the rotors turn.

Each speed sensor detects that magnetic change and sends a pulse signal to the skid control ECU (brake actuator assembly).

HINT:

When the connectors between the speed sensor and skid control ECU (brake actuator assembly) are connected, the following waveform is output.

| DTC No. | Detection Item | DTC Detection Condition | Trouble Area |

|---|---|---|---|

| C05061F | Right Front Wheel Speed Sensor Circuit Intermittent | Any of the following is detected:

|

|

*: w/ AVS

DTC Detection Conditions : C05061F| Vehicle Condition | ||||

|---|---|---|---|---|

| Pattern 1 | Pattern 2 | Pattern 3 | ||

| Diagnosis Condition | When the +BS terminal voltage is 17.4 V or less | ○ | - | - |

| When the +BS terminal voltage is 17.4 V or less at a vehicle speed of 10 km/h (6 mph) or more | - | - | ○ | |

| When the +BS terminal voltage is 17.4 V or less at a vehicle speed of 20 km/h (12 mph) or more | - | ○ | - | |

| Malfunction Status | An open in the sensor signal circuit of a malfunctioning area occurs 255 times or more | ○ | - | - |

| Noise occurs in the sensor signals of a malfunctioning wheel 75 times or more within 5 seconds | - | ○ | - | |

| Noise occurs once per rotor rotation | - | - | ○ | |

| Detection Time | - | - | 15 seconds or more | |

| Number of Trips | 1 trip | 1 trip | 1 trip | |

HINT:

DTC will be output when conditions for any of the patterns in the table above are met.

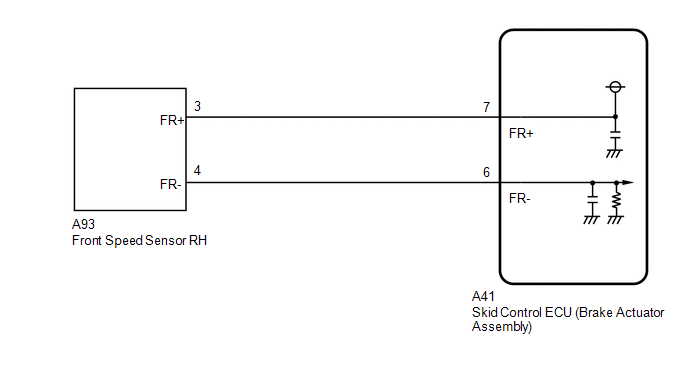

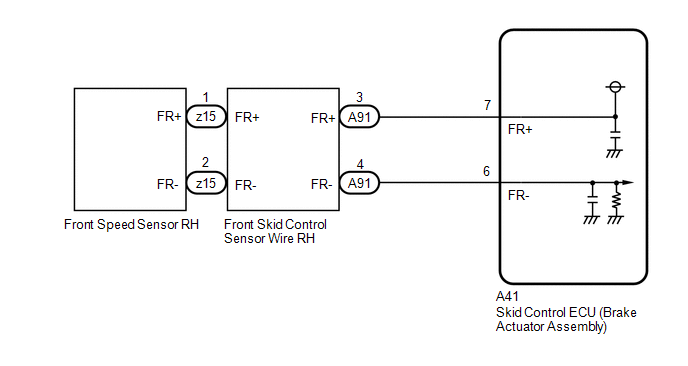

WIRING DIAGRAM

w/o AVS w/ AVS

w/ AVS

CAUTION / NOTICE / HINT

NOTICE:

-

After replacing the skid control ECU (brake actuator assembly), perform "Calibration".

Click here

.gif)

-

After replacing or removing and installing a speed sensor, perform Dealer Mode (Signal Check) inspection to confirm that the speed sensors are operating correctly.

Click here

.gif)

-

After replacing or removing a speed sensor rotor, perform Dealer Mode (Signal Check) inspection to confirm that the speed sensors are operating correctly.

Click here

.gif)

PROCEDURE

| 1. | READ VALUE USING TECHSTREAM (MOMENTARY INTERRUPTION) |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Enter the following menus: Chassis / Brake/EPB / Data List.

Chassis > Brake/EPB > Data List| Tester Display | Measurement Item | Range | Normal Condition | Diagnostic Note |

|---|---|---|---|---|

| FR Speed Sensor Voltage Open | Front speed sensor RH voltage open detection | Under intermittent / Normal | Under intermittent: Momentary interruption detected Normal: Momentary interruption not detected | - |

| Tester Display |

|---|

| FR Speed Sensor Voltage Open |

(d) Select the line graph display.

(e) Check for any momentary interruption in the wire harness and connector.

Click here .gif)

OK:

Normal (There are no momentary interruptions.)

NOTICE:

Perform the above inspection before removing the sensor and connector.

| NG | .gif) | GO TO STEP 5 |

|

| 2. | READ VALUE USING TECHSTREAM (FR WHEEL SPEED) |

(a) Enter the following menus: Chassis / Brake/EPB / Data List.

Chassis > Brake/EPB > Data List| Tester Display | Measurement Item | Range | Normal Condition | Diagnostic Note |

|---|---|---|---|---|

| FR Wheel Speed | Front wheel speed sensor RH reading | Min.: 0.0 km/h (0.0 mph) Max.: 6553.5 km/h (4072 mph) | Vehicle stopped: 0.0 km/h (0.0 mph) | When driving at constant speed: No large fluctuations |

| Tester Display |

|---|

| FR Wheel Speed |

(b) Start the engine.

(c) Perform a road test.

(d) Check the speed value output from the speed sensor displayed on the Techstream.

HINT:

Factors that affect the indicated vehicle speed include tire size, tire pressure, and tire wear. The speed indicated on the speedometer has an allowable margin of error. This can be tested using a speedometer tester (calibrated chassis dynamometer). For details about testing and the margin of error, see the reference chart.

Click here .gif)

OK:

The speed value output from the speed sensor displayed on the Techstream is similar to the speed indicated on the speedometer.

| NG | .gif) | GO TO STEP 5 |

|

| 3. | CLEAR DTC |

(a) Operate the Techstream to clear the codes. Enter the following menus: Chassis / Brake/EPB / Trouble Codes.

Chassis > Brake/EPB > Clear DTCs(b) Press the DTC clear button.

(c) Turn the engine switch off.

|

| 4. | RECONFIRM DTC |

(a) Start the engine.

(b) Perform a road test.

(c) Read the DTCs following the prompts on the Techstream. Enter the following menus: Chassis / Brake/EPB / Trouble Codes.

Chassis > Brake/EPB > Trouble Codes(d) Check if the same DTC is output.

| Result | Proceed to |

|---|---|

| DTC C05061F is not output. | A |

| DTC C05061F is output. | B |

| A | .gif) | USE SIMULATION METHOD TO CHECK |

| B | .gif) | REPLACE BRAKE ACTUATOR ASSEMBLY |

| 5. | CHECK FRONT SPEED SENSOR RH INSTALLATION |

| (a) Turn the engine switch off. |

|

(b) Check the front speed sensor RH installation.

OK:

There is no clearance between the front speed sensor RH and steering knuckle.

The installation bolt is tightened properly.

Torque

8.5 N*m (87 kgf*cm, 75 in.*lbf)

| NG | .gif) | REINSTALL OR REPLACE FRONT SPEED SENSOR RH |

|

| 6. | CHECK FRONT SPEED SENSOR RH AND FRONT SPEED SENSOR ROTOR RH (CHECK FOR FOREIGN MATTER) |

(a) Remove the front speed sensor RH and the component with the front speed sensor rotor RH.

for front speed sensor RH: Click here .gif)

for front speed sensor rotor RH: Click here .gif)

(b) Check the front speed sensor RH tip and front speed sensor rotor RH.

OK:

No scratches, oil, or foreign matter on the front speed sensor RH tip and front speed sensor rotor RH.

NOTICE:

- If there is oil or foreign matter on the front speed sensor RH, clean the front speed sensor RH.

- If the front speed sensor RH is damaged, replace the front speed sensor RH with a new one.

- Do not use parts cleaner when cleaning the front speed sensor rotor RH.

- If the front speed sensor rotor RH is damaged, replace the front speed sensor rotor RH with a new one.

HINT:

- The front speed sensor rotor RH is incorporated into the front axle hub sub-assembly RH.

- If the front speed sensor rotor RH needs to be replaced, replace it together with the front axle hub sub-assembly RH.

| NG | .gif) | CLEAN OR REPLACE FRONT SPEED SENSOR RH OR COMPONENT WITH FRONT SPEED SENSOR ROTOR RH |

|

| 7. | CHECK VEHICLE SPECIFICATION |

(a) Check the vehicle specification.

| Result | Proceed to |

|---|---|

| w/o AVS | A |

| w/ AVS | B |

| B | .gif) | GO TO STEP 10 |

|

| 8. | INSPECT HARNESS AND CONNECTOR (FRONT SPEED SENSOR RH - BRAKE ACTUATOR ASSEMBLY) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(b) Disconnect the A41 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the A93 front speed sensor RH connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| A93-3 (FR+) - A41-7 (FR+) | Always | Below 1 Ω |

| A93-3 (FR+) or A41-7 (FR+) - Body ground | Always | 10 kΩ or higher |

| A93-4 (FR-) - A41-6 (FR-) | Always | Below 1 Ω |

| A93-4 (FR-) or A41-6 (FR-) - Body ground | Always | 10 kΩ or higher |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 9. | INSPECT BRAKE ACTUATOR ASSEMBLY (SENSOR POWER SOURCE CIRCUIT) |

| (a) Reconnect the A41 skid control ECU (brake actuator assembly) connector. |

|

(b) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(c) Turn the engine switch on (IG).

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| A93-3 (FR+) - Body ground | Engine switch on (IG) | 11 to 14 V |

| OK | .gif) | REPLACE FRONT SPEED SENSOR RH |

| NG | .gif) | REPLACE BRAKE ACTUATOR ASSEMBLY |

| 10. | INSPECT FRONT SKID CONTROL SENSOR WIRE RH |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the z15 and A91 front skid control sensor wire RH connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| z15-1 (FR+) - A91-3 (FR+) | Always | Below 1 Ω |

| z15-1 (FR+) or A91-3 (FR+) - Body ground and other terminals | Always | 10 kΩ or higher |

| z15-2 (FR-) - A91-4 (FR-) | Always | Below 1 Ω |

| z15-2 (FR-) or A91-4 (FR-) - Body ground and other terminals | Always | 10 kΩ or higher |

| NG | .gif) | REPLACE FRONT SKID CONTROL SENSOR WIRE RH |

|

| 11. | CHECK HARNESS AND CONNECTOR (FRONT SKID CONTROL SENSOR WIRE RH - BRAKE ACTUATOR ASSEMBLY) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(b) Disconnect the A41 skid control ECU (brake actuator assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| A91-3 (FR+) - A41-7 (FR+) | Always | Below 1 Ω |

| A91-3 (FR+) or A41-7 (FR+) - Body ground | Always | 10 kΩ or higher |

| A91-4 (FR-) - A41-6 (FR-) | Always | Below 1 Ω |

| A91-4 (FR-) or A41-6 (FR-) - Body ground | Always | 10 kΩ or higher |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 12. | INSPECT BRAKE ACTUATOR ASSEMBLY (SENSOR POWER SOURCE CIRCUIT) |

| (a) Reconnect the A41 skid control ECU (brake actuator assembly) connector. |

|

(b) Reconnect the A91 front skid control sensor wire RH connector.

(c) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(d) Turn the engine switch on (IG).

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| z15-1 (FR+) - Body ground | Engine switch on (IG) | 11 to 14 V |

| OK | .gif) | REPLACE FRONT SPEED SENSOR RH |

| NG | .gif) | REPLACE BRAKE ACTUATOR ASSEMBLY |

Right Front Wheel Speed Sensor Circuit Short to Ground or Open (C050614)

Right Front Wheel Speed Sensor Circuit Short to Ground or Open (C050614)

DESCRIPTION Refer to DTC C05061F. Click here DTC No. Detection Item DTC Detection Condition Trouble Area C050614 Right Front Wheel Speed Sensor Circuit Short to Ground or Open An op ...

Right Front Wheel Speed Sensor Signal Stuck Low (C050623)

Right Front Wheel Speed Sensor Signal Stuck Low (C050623)

DESCRIPTION Refer to DTC C05061F. Click here DTC No. Detection Item DTC Detection Condition Trouble Area C050623 Right Front Wheel Speed Sensor Signal Stuck Low Any of the following ...

Other materials:

Lexus RX (RX 350L, RX450h) 2016-2025 Repair Manual > Rear Air Conditioning Unit: Components

COMPONENTS ILLUSTRATION *1 AIR CONDITIONING HOSE AND ACCESSORY *2 NO. 1 LUGGAGE COMPARTMENT SIDE COVER PROTECTOR *3 SUCTION TUBE *4 LIQUID TUBE *5 INLET HEATER WATER HOSE *6 OUTLET HEATER WATER HOSE *7 REAR WHEEL HOUSE LINER RH *8 GROMMET *9 O-RING - ...

Lexus RX (RX 350L, RX450h) 2016-2025 Repair Manual > Audio And Visual System (for 8 Inch Display): Registered Device cannot be Deleted

PROCEDURE 1. DELETE OPERATION (a) Check if a registered portable player can be deleted normally. OK: Registered portable player can be deleted normally. OK END NG PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE ...

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Owners Manual

- For your information

- Pictorial index

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Lexus Display Audio system

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Repair Manual

0.015

.gif)